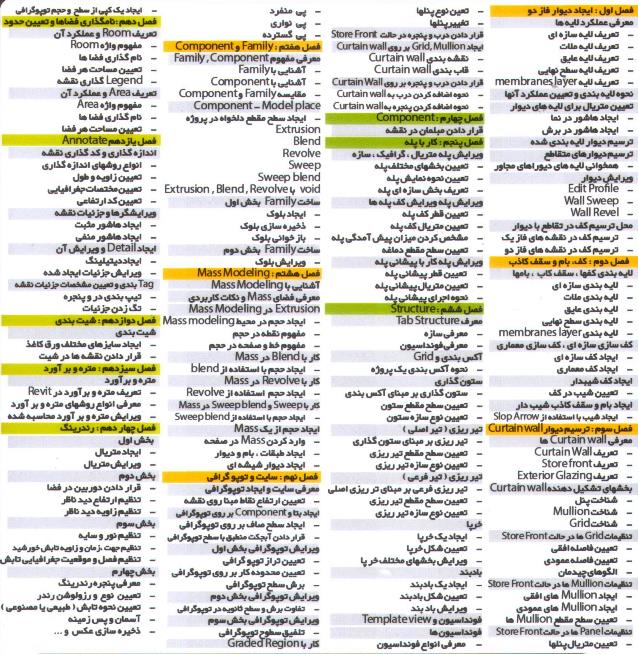

The American Institute of Steel Construction (AISC), reporting on the construction costs of structural steel buildings in this article, shares that 46% of a typical structural steel package is attributed to fabrication alone and goes on to share that “ can reduce the cost of a steel package by 10% to 20%.” (AISC) Detailers and fabricators are critical stakeholders in maximizing the full potential of a structural steel BIM workflow. It also requires engagement from the trades. The growing importance of BIM is not limited to only adoption by designers and contractors. This gave AutoCAD users a pathway to BIM and provided detailers the tools to execute on projects and grow competitively within a changing project delivery landscape. We acquired Advance Steel with the vision to connect design and construction through fabrication.

In 2014, we invested more deliberately in the steel fabrication industry. I can tell you with certainty that when designing a complex building, with Revit, the time is halved and therefore the production is doubled.” Matteo Scussel, MTC Studio di Ingegneria “ errors are reduced to a minimum and the speed of creating the bar bending schedules and making any correction of errors is very fast. One such customer is Matteo Scussel of MTC Studio di Ingegneria, who shared: Many customers since have shared their success stories after evolving their workflows to include BIM, as shared in this blog post from 2021. About a half-dozen years ago, we made substantial strides in developing concrete detailing capabilities in Revit.

One recent example being our investment in the concrete detailing space. Since the inception of BIM in the early 2000s, we have worked to bring the benefits of BIM to our users throughout the structures industry and sub-industries. Autodesk is connecting structural steel to BIM.

0 kommentar(er)

0 kommentar(er)